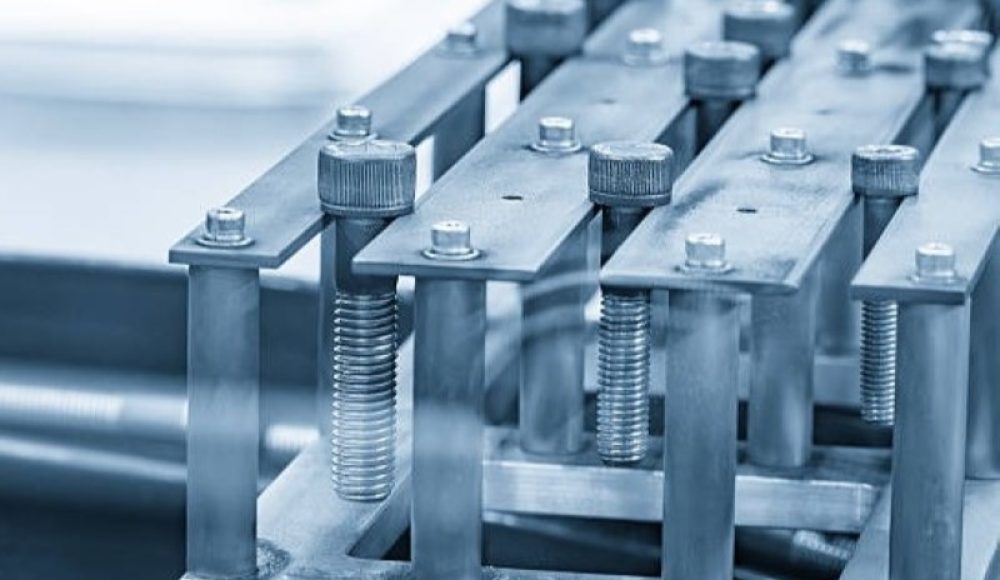

مسامير غطاء رأس المقبس تستخدم على نطاق واسع في الهندسة, السيارات, والتجمعات الصناعية بسبب قوتها العالية وملاءمتها الدقيقة. لكن, يعتمد أدائها بشكل كبير على عزم الدوران الصحيح المطبق أثناء التثبيت. يحدد عزم الدوران قوة التثبيت التي تربط المكونات معًا, ضمان الاستقرار تحت الاهتزاز والحمل. عندما يكون عزم الدوران منخفضًا جدًا, قد يخفف المسمار مع مرور الوقت. على العكس من ذلك, يمكن أن يؤدي عزم الدوران المفرط إلى تمدد الخيوط أو إتلافها, تقليل القوة الشاملة. لذلك, يعد تحقيق توازن عزم الدوران الصحيح أمرًا ضروريًا للحفاظ على السلامة الميكانيكية للجمعيات.

دور التشديد في ضمان الاعتمادية الهيكلية

إن ربط المسمار ليس مجرد عمل ميكانيكي ولكنه عملية خاضعة للرقابة تؤثر بشكل مباشر على توزيع التحميل المسبق. يساعد الشد المناسب في الحفاظ على توتر ثابت عبر عمود المسمار, مما يسمح لمسامير غطاء رأس المقبس بمقاومة القوى الخارجية بشكل فعال. في المعدات الدقيقة أو الآلات, يمكن أن يؤدي التشديد غير المتساوي إلى اختلال المحاذاة, مما يؤدي إلى تعب المكونات والتآكل المبكر. يضمن استخدام مفاتيح عزم الدوران المعايرة أو أدوات الشد الآلية تطبيقًا دقيقًا للتحميل المسبق, مما يساعد على منع كل من الشد الزائد والإفراط في الشد. تعمل هذه الطريقة أيضًا على تحسين التكرار والموثوقية على المدى الطويل.

التحكم في عزم الدوران لأداء التثبيت الأمثل

في بيئات الضغط العالي, مثل صناعة الطيران أو صناعة السيارات, يصبح التحكم في عزم الدوران أمرًا بالغ الأهمية. غالبًا ما يستخدم المهندسون علاقات عزم الدوران والشد لحساب مستوى الشد المثالي. على سبيل المثال, عوامل مثل صلابة المواد, تزييت الخيط, والاحتكاك السطحي يمكن أن يؤثر جميعًا على كيفية ترجمة عزم الدوران إلى قوة تثبيت. من خلال مراقبة هذه المعلمات بعناية, يمكن للمستخدمين الحفاظ على أداء لولبي ثابت تحت التمدد الحراري أو الأحمال الديناميكية. علاوة على ذلك, يمكن أن يؤدي الفحص الدوري وإعادة عزم الدوران للمثبتات إلى تحسين عمر الخدمة والسلامة بشكل كبير.

أهمية معايير عزم الدوران المتسقة

يعد إنشاء معايير عزم دوران متسقة أمرًا حيويًا لكل من المصنعين والمستخدمين النهائيين. تساعد قيم عزم الدوران القياسية المستندة إلى حجم المسمار والمواد على التخلص من التخمين أثناء التجميع. لمسامير غطاء رأس المقبس, الحفاظ على عزم الدوران الموحد يضمن توزيع الضغط بشكل متوازن, منع فشل المفاصل. في التطبيقات الصناعية, يمكن لأنظمة الأتمتة دمج أجهزة استشعار مراقبة عزم الدوران لتسجيل بيانات التشديد لضمان الجودة. لا تعمل هذه التدابير على تحسين دقة التجميع فحسب، بل تعمل أيضًا على بناء ثقة المشتري في موثوقية المنتج.

تعزيز كفاءة أدوات التثبيت من خلال الربط المناسب

يركز CHE على توفير تم تصميم مسامير غطاء رأس المقبس للدقة والقوة. تضمن عملية التصنيع لدينا أن كل أداة تثبيت تلبي مواصفات عزم الدوران والشد الصارمة. من خلال الجمع بين معالجات المواد المتقدمة والخيوط الأمثل, تحافظ منتجاتنا على مقاومة عزم الدوران الفائقة والحد الأدنى من التشوه حتى في ظل الحمل العالي. هذا النهج يضمن الأداء العالي, تحضير السحابات تشي مثالية للبيئات الصعبة التي يكون فيها التشديد الدقيق والتثبيت المتسق أمرًا بالغ الأهمية.

خاتمة

يعد عزم الدوران والشد أمرًا أساسيًا لأداء وطول عمر براغي غطاء رأس المقبس. من خلال فهم كيفية تفاعل هذه العوامل, يمكن للمهندسين تحقيق أقوى, أكثر استقرارا, وتجمعات أكثر أمانًا. حيث أن دقة عزم الدوران تؤثر بشكل مباشر على السلامة الهيكلية, اختيار السحابات الجودة من الشركات المصنعة الموثوقة مثل CHE يضمن المتانة, تناسق, وكفاءة طويلة الأمد في كل تطبيق.