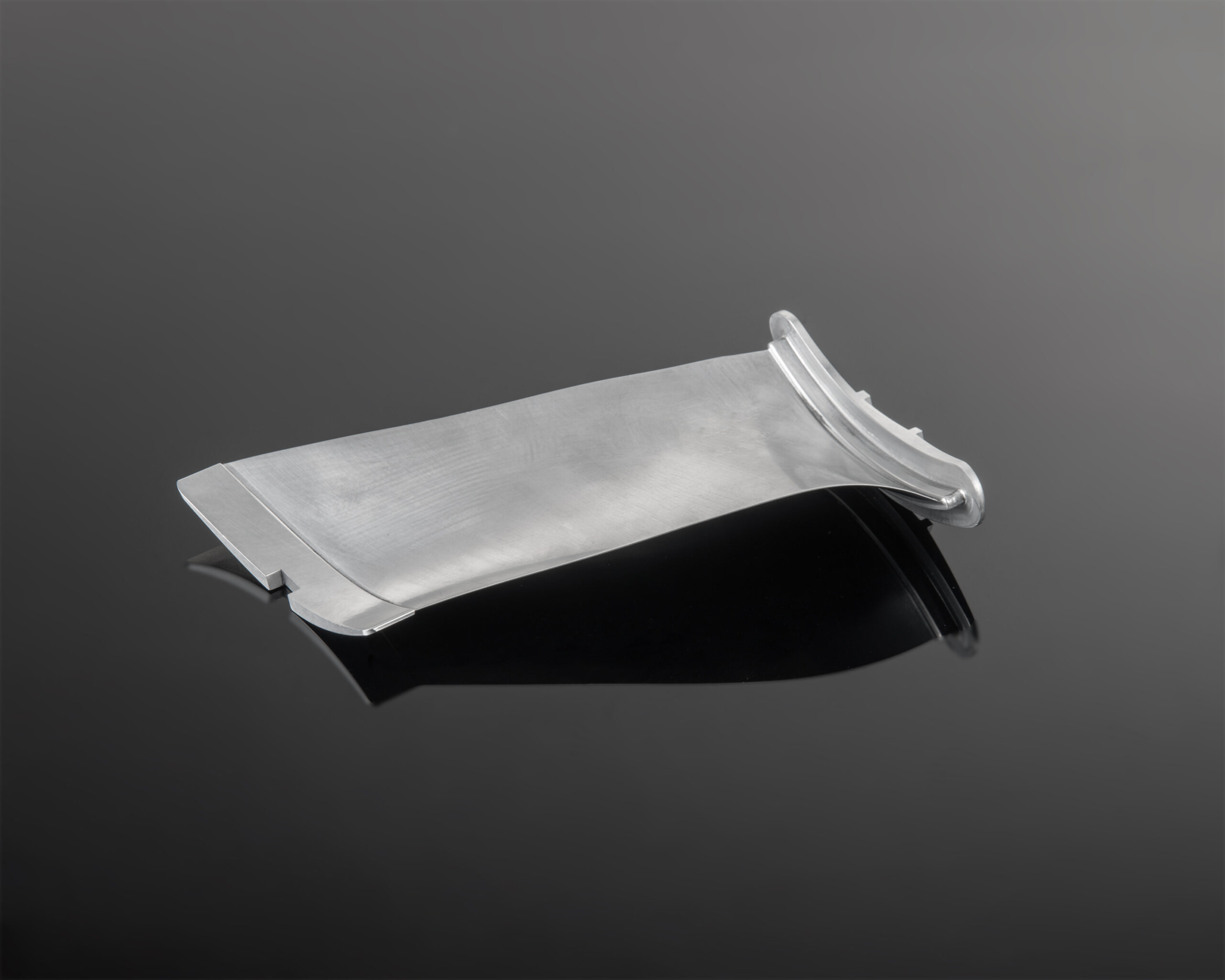

Steel Hardened Aerospace Parts – CNC Machining ±0.005mm

ملكنا steel hardened aerospace parts are engineered for mission-critical applications where precision, strength, and reliability are non-negotiable. Designed for use in aircraft structures, engines, satellites, and space systems, these components deliver consistent performance under extreme mechanical and environmental conditions.

Aerospace-Grade Precision Manufacturing

Using advanced 5-axis CNC machining and Swiss-type turning centers, we achieve dimensional tolerances as tight as ±0.005 mm. Complex geometries, fine features, and tight assemblies are produced with exceptional repeatability, ensuring seamless integration into aerospace systems.

Certified Materials & Hardened Performance

We manufacture steel hardened aerospace parts exclusively from certified aerospace-grade materials, including high-performance stainless steels such as A286 and 17-4PH, ensuring traceability and compliance with AS9100 and ISO 9001 standards. Precision heat treatment enhances hardness, قوة الشد, مقاومة التعب, and long-term durability.

Advanced Forming & Structural Integrity

Cold heading and thread rolling processes optimize grain flow and improve fatigue life, making these components ideal for applications exposed to vibration, cyclic loads, and thermal stress. Each part is engineered to maintain structural integrity throughout extended service life.

Surface Engineering for Harsh Environments

Depending on application requirements, components can receive passivation, cadmium plating, phosphate coating, anodizing, or dry film lubrication to improve corrosion resistance, wear performance, and assembly efficiency.

Comprehensive Inspection & Quality Assurance

Every batch of steel hardened aerospace parts undergoes rigorous inspection, including NDT methods such as ultrasonic testing, X-ray inspection, and dye penetrant testing. Dimensional verification is performed using CMM systems, optical comparators, and 3D metrology equipment.

Custom Aerospace Engineering Support

From prototype development to serial production, we provide engineering collaboration tailored to specific aircraft platforms, defense programs, or space missions—supporting both standard and highly customized aerospace fastening and structural solutions.