В современном машиностроении и производстве, vibration control is critical to product safety and performance. Whether in automotive systems, aerospace components, or industrial machinery, fasteners must maintain strong joint integrity under continuous movement. Among many fastening solutions, метрические самоконтрящиеся болты stand out for their ability to maintain stability in high-vibration environments.

Understanding the Principle of Self-Locking

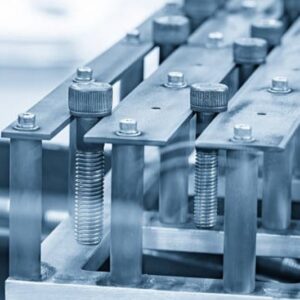

Unlike traditional bolts that rely solely on friction, метрические самоконтрящиеся болты incorporate mechanical or chemical locking mechanisms to prevent loosening. These mechanisms often use nylon inserts, deformed threads, or wedge-lock designs. As vibration increases, the locking element resists rotational movement, maintaining torque and preventing back-off. Более того, this design ensures a consistent clamping force even after prolonged operation, reducing the risk of mechanical failure.

Performance Under High Vibration

In high-vibration environments, such as engines or turbines, standard fasteners tend to lose preload over time. Однако, самоконтрящиеся болты resist this effect due to their unique locking structure. They can withstand both axial and transverse vibrations while maintaining strong friction between threads. Кроме того, the metric standard ensures uniform compatibility, precision fit, and optimal torque distribution across multiple assembly types. Поэтому, these bolts perform exceptionally well in dynamic systems where traditional fasteners often fail.

Material and Durability Advantages

To enhance resistance to stress and fatigue, метрические самоконтрящиеся болты are commonly made from high-grade steel, нержавеющая сталь, or alloy materials. These materials provide superior tensile strength and corrosion resistance. Более того, surface treatments such as zinc plating or anti-corrosion coatings improve long-term durability in harsh industrial settings. This combination of mechanical strength and environmental protection makes them ideal for heavy-duty applications.

Practical Applications and Reliability

Practical Applications and Reliability

Metric self-locking bolts are widely used in transportation equipment, vibration platforms, and precision machinery. In automotive assemblies, they secure engine mounts, системы подвески, and brake components, where continuous vibration occurs. In the aerospace and wind power industries, they guarantee connection reliability even under extreme motion and temperature changes. Through their anti-loosening design, they reduce maintenance frequency and improve operational safety.

Choosing the Right Bolt for the Job

When selecting самоконтрящиеся болты, it is essential to match the bolt’s material, size, and locking mechanism to the vibration level and environmental conditions. Кроме того, users should consider factors such as preload requirements, installation torque, and reusability. A properly chosen bolt ensures consistent performance while minimizing maintenance costs. As a trusted fastener supplier, ЧТО offers a wide range of metric self-locking bolts designed for stability, точность, и долговечность.

Заключение

В заключение, метрические самоконтрящиеся болты provide outstanding resistance to loosening and mechanical fatigue in high-vibration environments. Their advanced locking design, durable materials, and metric precision make them essential components for modern engineering applications. As industries continue to demand higher reliability and performance, these bolts remain a crucial solution for vibration-prone systems.