Automotive fasteners are essential components that hold vehicles together, ensuring structural integrity, safety, et les performances. These small yet crucial parts play a significant role in assembling engines, châssis, body panels, and interior features. This blog explores the importance of automotive fasteners and why CHE Precision Group is your best choice for high-quality fastening solutions.

The Role of Automotive Fasteners in Vehicle Manufacturing

Fasteners are used in various automotive applications, securing critical components and ensuring durability. Key features of high-performance automotive fasteners include:

- High Strength & Durabilité: Designed to withstand extreme conditions, vibrations, and temperature changes.

- Corrosion Resistance: Made from stainless steel, titane, and coated materials for longevity.

- Precision Engineering: Ensures exact fitment to meet vehicle safety standards.

- Lightweight & Efficient Design: Optimized to reduce overall vehicle weight without compromising strength.

- Customizable Solutions: Available in different sizes, matériels, and coatings for various automotive applications.

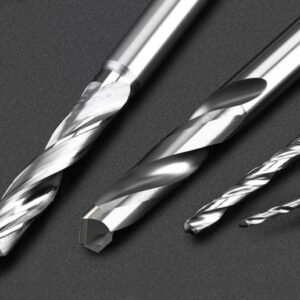

Types of Automotive Fasteners

- Boulons & Vis: Secure major engine components, systèmes de suspension, and structural parts.

- Noix & Rondelles: Provide stability and distribute load to prevent loosening.

- Clips & Retainers: Attach interior panels, wiring harnesses, and body trim.

- Rivets & Crampons: Essential for assembling high-stress areas like the chassis and body frame.

- Threaded Inserts: Enhance joint strength in softer materials like aluminum or plastic components.

Benefits of High-Quality Automotive Fasteners

- Enhanced Vehicle Safety: Prevents parts from loosening under high-speed and high-stress conditions.

- Increased Durability: Ensures longevity by resisting wear, vibration, and environmental damage.

- Optimized Vehicle Performance: Reduces weight while maintaining strength, improving fuel efficiency.

- Simplified Assembly & Maintenance: Facilitates easy installation and repair for automotive manufacturers and technicians.

- Compliance with Industry Standards: Meets strict automotive regulations for safety and reliability.

Why Choose CHE Precision Group?

CHE Precision Group is a trusted leader in the automotive fastener industry, delivering high-performance fastening solutions tailored to automotive needs. Here’s why we are the preferred choice:

- Advanced Manufacturing Technology: We use state-of-the-art CNC machining and cold forging for precision engineering.

- High-Quality Materials: Our fasteners are made from premium-grade steel, aluminium, and alloys to ensure durability.

- Custom Fastener Solutions: We provide specialized fasteners designed for specific vehicle applications.

- Strict Quality Control: Our products undergo rigorous testing to meet international automotive safety standards.

- Reliable Supply Chain & Fast Delivery: We ensure timely production and delivery to keep your manufacturing on schedule.

Contactez-nous

Looking for top-quality automotive fasteners? Groupe CHE Précision provides durable, high-performance fastening solutions to enhance vehicle safety and performance. Contact us today to learn more about our products and how we can support your automotive needs!