The modern industrial landscape increasingly relies on high-performance and reliable components. Among them, threaded precision fasteners have emerged as critical elements in industries demanding accuracy, safety, and long-term durability. From electronics to medical devices and precision instruments, the requirement for custom fasteners continues to expand. Manufacturers and designers seek fasteners that deliver consistent performance, meet strict tolerances, and ensure operational stability in demanding environments.

This article explores the rising demand for custom threaded precision fasteners, focusing on their essential role, material selection, precision standards, and applications across specialized industries.

Electronics Industry: Supporting Miniaturization and Performance

The electronics sector has experienced rapid innovation, driving the need for miniature and high-precision threaded fasteners. Devices such as smartphones, wearables, and IoT gadgets require fasteners that occupy minimal space without compromising structural integrity.

Material choice and manufacturing precision are crucial. Fasteners must endure thermal expansion, vibration, and mechanical stress while maintaining electrical insulation or conductivity where necessary. Metals like stainless steel, titanio, and high-strength alloys are commonly used for their durability and corrosion resistance.

Custom fasteners allow engineers to adapt thread types, longitudes, and diameters to meet specific device requirements. Precision machining ensures that even sub-millimeter screws fit seamlessly, preventing malfunctions and supporting device longevity.

Dispositivos médicos: Prioritizing Safety and Reliability

In the medical field, safety and reliability are non-negotiable. Custom threaded fasteners are integral in surgical instruments, diagnostic equipment, and implantable devices.

These fasteners must adhere to strict biocompatibility standards. Materials such as medical-grade stainless steel and titanium are widely adopted for their resistance to corrosion and ability to maintain integrity in sterile environments.

Moreover, precision threads minimize loosening risks and guarantee stable connections in critical applications. Reliable fasteners support repeated assembly and disassembly during maintenance, ensuring device longevity. The combination of tight tolerances and robust materials ensures that medical devices operate safely under high-stress conditions.

Precision Instruments: Accuracy and Stability

Precision instruments, including optical devices, laboratory tools, and measurement equipment, demand fasteners that provide accuracy and stability over time. Environmental factors like humidity, vibration, and temperature changes must not compromise structural performance.

Custom fasteners in these applications often feature specialized coatings or treatments to enhance wear resistance and corrosion protection. Engineers may specify thread designs that balance load distribution with minimal material deformation, ensuring repeatable precision in sensitive instruments.

The ability to produce high-precision, customized screws allows manufacturers to meet stringent standards while maintaining operational reliability. Threaded precision fasteners in these contexts are not merely connectors; they are foundational components that uphold the entire instrument’s integrity.

Advantages of Custom Threaded Precision Fasteners

-

Especificaciones a medida: Custom fasteners can be manufactured to exact dimensions, thread pitches, and mechanical properties.

-

Enhanced Performance: High-quality materials and precision engineering reduce wear, prevent loosening, and support high-stress applications.

-

Compliance and Safety: Fasteners meet industry standards, ensuring safety in sensitive sectors like medical devices and aerospace.

-

Versatility: Suitable for miniature electronics, complex machinery, and precision instruments.

-

Longevity: Properly engineered fasteners extend the service life of equipment and reduce maintenance requirements.

Material Selection and Manufacturing Considerations

Material selection directly impacts the performance of threaded precision fasteners. Stainless steel, titanio, and specialty alloys provide strength, corrosion resistance, and durability. Tratamientos superficiales, such as passivation or plating, further enhance performance under challenging conditions.

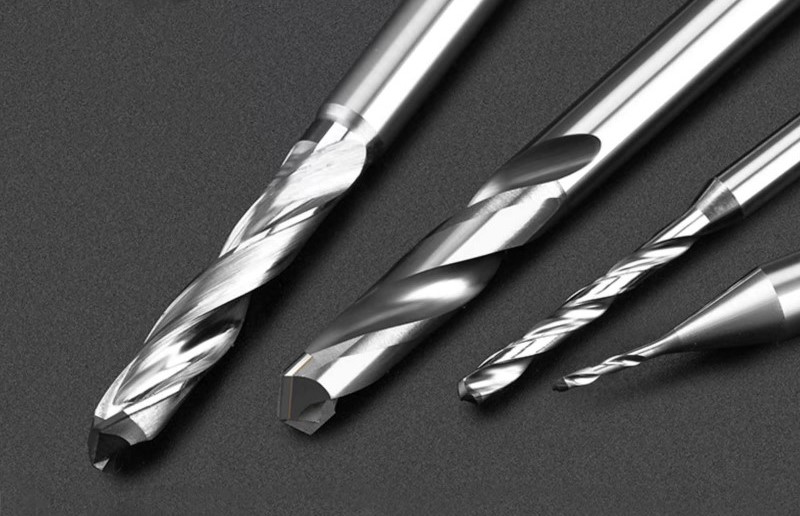

Manufacturing processes like CNC machining, thread rolling, and micro-drilling allow for tight tolerances and repeatable quality, essential for applications where even minor deviations can affect device functionality.

Custom fasteners may also include design modifications like captive threads, non-standard diameters, or asymmetric profiles to meet unique assembly needs. Such features are increasingly important as devices and instruments become more compact and sophisticated.

Industry Applications Summary

-

Electronics: Miniature screws for smartphones, wearables, and IoT devices.

-

Dispositivos médicos: Biocompatible fasteners for surgical instruments, implants, and diagnostic equipment.

-

Precision Instruments: Durable fasteners for optical, measurement, and laboratory tools.

Across these industries, threaded precision fasteners are not optional components—they are essential for device integrity, operational reliability, and long-term durability.

Future Trends in Custom Fastener Demand

The demand for custom threaded precision fasteners is expected to continue rising as industries adopt more advanced technologies. Miniaturization, higher-performance requirements, and stricter safety standards will drive the need for specialized fasteners.

Manufacturers will increasingly focus on innovative materials, precise machining techniques, and specialized coatings to meet these evolving demands. The future will favor suppliers capable of delivering reliable, durable, and highly customized solutions.

Conclusión

Custom threaded precision fasteners are fundamental to modern electronics, medical devices, and precision instruments. Their importance stems from their ability to combine precision, durabilidad, and compliance in demanding applications.

For specialized industries, the selection of high-quality fasteners directly impacts product performance, safety, and longevity. Companies focusing on custom solutions ensure that devices operate reliably, maintain structural integrity, and meet exacting standards.

Investing in threaded precision fasteners is more than a mechanical choice—it is a strategic decision to enhance product quality, operational safety, and long-term reliability in industries where precision matters most.